GRJS-6001 Tap Water/Sewage Integrated Automatic Control System

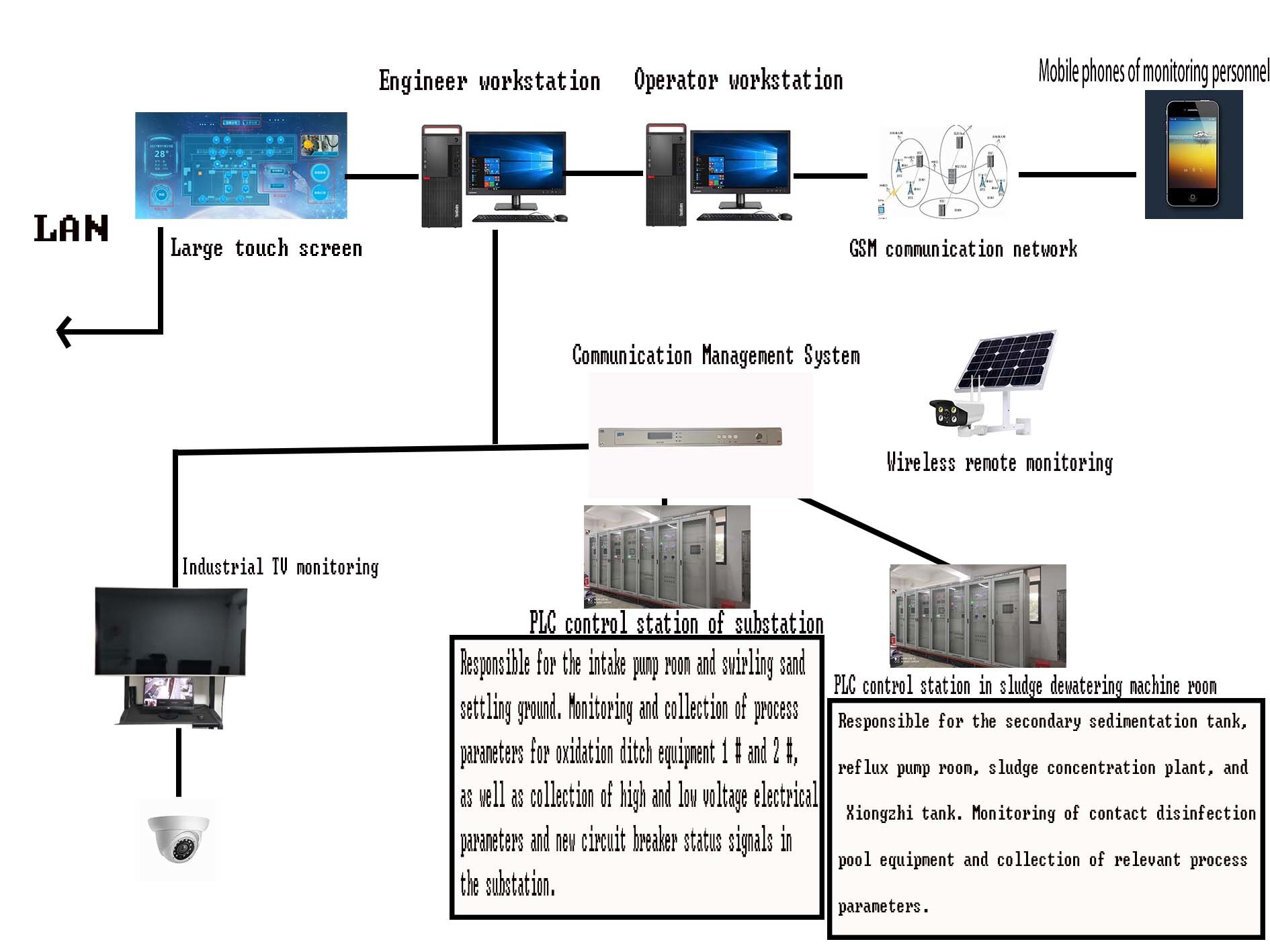

GRJS-6001 tap water/sewage integrated automatic control system is mainly used in sewage treatment, waterworks and water supply dispatching information system. The system is composed of computer monitoring, microcomputer protection, process control system and power supply system, which is used for protection, control, measurement and monitoring of water treatment system, and it has the interface for communication with dispatching center, and completes the functions of telemetry, remote communication, remote control and remote adjustment.

关键词:

Keywords:

Electrical equipment | electrical automation

Category:

Description

Product Introduction

GRJS-6001 tap water/sewage integrated automatic control system is mainly used in sewage treatment, waterworks and water supply dispatching information system. The system is composed of computer monitoring, microcomputer protection, process control system and power supply system, which is used for protection, control, measurement and monitoring of water treatment system, and it has the interface for communication with dispatching center, and completes the functions of telemetry, remote communication, remote control and remote adjustment.

The overall design of the system is based entirely on the principle of "fewer people on duty", which can achieve operation monitoring, automatic control, information technology, and modern management of the whole station.

Main functions

♦ GRJS-6001 water treatment integrated automation system supports Windows and Linux cross-platform applications, and different operating systems have the same basic functions and advanced application software functions.

♦ It can collect the parameters of incoming and outgoing water flow, sewage turbidity, PH value, water level before and after the coarse grate, water level of suction well in pumping room, oxidation ditch water level, dissolved oxygen in front and back section, return sludge amount, return sludge concentration, water level of suction well in pumping room, residual sludge flow, drug tank level, outgoing water flow, ammonia nitrogen, turbidity, PH value and so on.

♦ It can achieve the condition detection and control of coarse and fine grilles, lifting pumps, electric valves, mixers, surface aerators, secondary sedimentation tank trusses, residual and return sludge pumps, dehydrators, dosing, transformer and distribution equipment.

♦ It can dynamically display the middle picture and sub-picture of the whole process, the state of the equipment and various parameter values.

♦ It can achieve fault alarm display, statistical analysis, printing, storage and other alarm processing.

♦ It can achieve the daily data processing, storage, information query and output of management reports.

♦ Data acquisition and data processing

♦ Security monitoring, animation display

♦ Real-time and historical database management

♦ Report printing management

♦ Intelligent voice alarm, ON-CALL

♦ Accident record and accident recall

♦ Operation record

♦ Equipment operation statistics and production management

♦ Intra-station and telecontrol communication

♦ Remote fault diagnosis and maintenance

Typical case

Zhangjiajie No.1 Water Plant in Hunan Province (daily water supply 200,000 tons)

Qingji Industrial Sewage Treatment Plant, Gong'an County, Hubei Province(80,000 tons/day)

Recommended products

Leave a message for consultation.